Bonfiglioli LC Series Inline Planetary Gearbox

The Bonfiglioli LC Series Inline Planetary Gearbox is a reliable two-stage inline drive solution, engineered for general industrial scenarios requiring stable coaxial torque transmission. As a foundational model optimized for versatility, it integrates precision planetary gear trains with hard-faced gears (surface hardness HRC 58-62), delivering transmission efficiency up to 95% and robust load-bearing capacity, suitable for continuous-duty operations. Designed to overcome leakage issues and reduce operational noise, it features a robust housing, lifelong synthetic lubrication, and a dual-seal system, achieving an IP54 protection rating to resist dust and minor moisture. With flexible mounting options and compatibility with IE3/IE4 efficient motors, it supports seamless integration into existing production lines. Widely applied in conveyors, packaging machinery, and general industrial equipment, it balances durability, maintenance convenience, and cost-effectiveness. Backed by Bonfiglioli’s expertise, it serves as a trusted basic drive solution for mainstream industrial needs. (300 words)

READ MORE...

Bonfiglioli SL Series Inline Planetary Gearbox

The Bonfiglioli SL Series Inline Planetary Gearbox is a precision-driven solution tailored for timing belt pulley drive systems and servo applications. Optimized with a compact inline structure, it integrates high-performance planetary gear trains to deliver exceptional positioning accuracy, high radial load capacity (6,000–15,000 N), and a transmission efficiency of up to 97%, making it ideal for both continuous and intermittent duty cycles. Available in three sizes (070/090/120) with 1-stage (3–10) and 2-stage (9–100) gear ratios, it covers a nominal torque range of 25–155 Nm, with reduced backlash options (≤6 arcmin for 1-stage, ≤8 arcmin for 2-stage). Equipped with lifelong synthetic lubrication and a dual-seal system, it achieves an IP54 protection rating, adapting to general industrial environments with minimal maintenance. Its standardized output design enables easy retrofits and seamless integration with servo motors. Widely used in belt-driven conveyors and precision automation, it balances compactness and reliability, backed by Bonfiglioli’s expertise. (300 words)

READ MORE...

Bonfiglioli MPE Series Inline Planetary Gearbox

The Bonfiglioli MPE Series Inline Planetary Gearbox is a high-efficiency precision drive solution engineered for industrial applications requiring coaxial torque transmission. Integrating optimized planetary gear trains with a compact inline structure, it delivers exceptional power density, transmission efficiency up to 97%, and high torsional rigidity, making it ideal for both servo control and continuous-duty scenarios. Crafted with hardened alloy steel gears (surface hardness HRC 58-62) processed by five-axis CNC machines, it ensures low backlash and smooth operation, withstanding short-term overload torque up to 200%. Adopting lifelong synthetic lubrication and a dual-seal system, it achieves an IP54 protection rating, adapting to general industrial environments with dust while minimizing maintenance needs. Its modular design enables flexible mounting and seamless integration with IE3/IE4 motors, aligning with global energy standards. Widely used in material handling, automation lines and precision machinery, it balances durability, versatility and cost-effectiveness, backed by Bonfiglioli’s professional support. (300 words)

READ MORE...

Bonfiglioli BMS Series Planetary Gearmotor

The Bonfiglioli BMS Series Planetary Gearmotor is an integrated high-precision drive solution, combining permanent magnet synchronous motors with precision planetary gearboxes to replace traditional separate gearhead-motor combinations. This synergy delivers revolutionary space-saving design, exceptional power density, and high performance, making it ideal for industrial automation scenarios demanding compactness and accuracy. Available in 5 gearbox sizes (060/070/090/130/160) and 14 motor variants, it offers flexible performance options with low, medium, and high overspeed configurations, covering a torque range of 45–1200 Nm and output speeds of 50–1500 rpm. Features include lifelong lubrication, IP65 protection rating, and quiet operation, ensuring reliability in continuous or cyclic duty cycles. Equipped with diverse feedback options and optional 24V DC holding brakes, it integrates seamlessly with servo systems. Widely used in material handling, packaging, and textile machinery, it balances efficiency, versatility, and durability, backed by Bonfiglioli’s mechatronic expertise. (300 words)

READ MORE...

Bonfiglioli MPEK Series Right Angel Planetary Gearbox

The Bonfiglioli MPEK Series Right Angle Planetary Gearbox is a versatile high-precision drive solution engineered for industrial applications requiring reliable 90-degree torque transmission. Integrating precision planetary gear trains with spiral bevel gears, it delivers excellent power density, transmission efficiency up to 97%, and ultra-low backlash, ensuring precise positioning and smooth operation for both servo control and heavy-duty workloads. Adopting a rugged cast iron housing and hardened alloy steel gears (surface hardness HRC 58-62), it boasts superior torsional rigidity and wear resistance, capable of withstanding short-term overload torque up to 200%. Equipped with lifelong synthetic lubrication and dual-seal structure, it achieves an IP65 protection rating, adapting to harsh environments with dust and moisture while reducing maintenance needs. Its modular design enables flexible mounting and seamless integration with IE3/IE4 motors, aligning with global energy standards. Widely used in material handling, automation lines and precision machinery, it balances durability and adaptability, backed by Bonfiglioli’s professional support. (300 words)

READ MORE...

Bonfiglioli TQFEK Series Right Angel Planetary Gearbox

The Bonfiglioli TQFEK Series Right Angle Planetary Gearbox is a high-efficiency drive solution tailored for industrial applications demanding precise 90-degree torque transmission. Integrating precision planetary gearing with spiral bevel gears, it achieves transmission efficiency up to 98%, along with exceptional power density and low backlash, ensuring stable performance in both precision control and heavy-duty scenarios. Adopting Bonfiglioli’s core technologies, it features a rugged housing, lifelong synthetic lubrication, and dual-seal structure, boasting an IP67 protection rating to resist dust, moisture, and vibration. Compatible with IE3/IE4 efficient motors, it aligns with global energy-saving standards. Its modular design enables flexible mounting and seamless integration with industrial control systems. Widely used in AGVs, robotics, and material handling, it balances durability and intelligence. Backed by professional support, it offers reliable operation with minimal maintenance, serving as a premium choice for high-performance right-angle drive needs. (300 words)

READ MORE...

Bonfiglioli KR Series Right Angel Planetary Gearbox

The Bonfiglioli KR Series Right Angle Planetary Gearbox is a high-performance传动 solution engineered for industrial applications demanding reliable 90-degree torque transmission. Integrating precision spiral bevel and planetary gearing, it delivers exceptional power density, low backlash, and high torsional rigidity, with a transmission efficiency of over 95%, making it suitable for both precision control and heavy-duty tasks. Crafted with a rigid cast iron housing and hardened alloy steel gears (surface hardness up to HRC 60±2), the KR Series boasts superior wear resistance and overload capacity, enduring harsh industrial environments with vibration, dust, and temperature fluctuations. Its modular design enables flexible mounting options and seamless integration with servo and standard motors. Widely applied in robotics, material handling, machine tools, and automation systems, it balances compact size and stable performance. Adhering to global quality standards, it ensures long service life with minimal maintenance, backed by Bonfiglioli’s professional support. (300 words)

READ MORE...

Bonfiglioli LCK Series Right Angel Planetary Gearbox

The Bonfiglioli LCK Series Right Angle Planetary Gearbox is a high-performance drive solution engineered for applications requiring efficient torque transmission at a 90-degree angle. Integrating precision planetary gearing with a compact right-angle design, it delivers exceptional power density, low backlash, and smooth operation, making it suitable for both light and heavy-duty industrial tasks. Crafted with rugged materials and optimized internal mechanics, the LCK Series boasts excellent durability and resistance to wear, ensuring stable performance in harsh environments with vibration, dust, or temperature fluctuations. Its modular design allows flexible mounting options and easy integration with various motors, enhancing adaptability across sectors. Adhering to global quality and safety standards, it guarantees reliable operation while minimizing maintenance needs. Widely applied in material handling, robotics, packaging machinery, and automation systems, it balances torque output and energy efficiency. Backed by Bonfiglioli’s professional support, the LCK Series stands as a cost-effective choice for precise right-angle drive requirements. (300 words)

READ MORE...

SEW R Series Helical Gearmotor low voltage

The SEW R Series Helical Gearmotor is a high-reliability low-voltage drive solution, engineered for industrial applications demanding efficient linear power transmission. Integrating precision helical gearing with compatible low-voltage motors (DR/DRE/DRN/DRU series), it delivers consistent high torque, minimal operational noise, and excellent energy efficiency, suitable for light to heavy-duty workloads across diverse sectors. Featuring a compact, coaxial design, it ensures easy installation in space-constrained environments while maintaining robust performance. The rugged housing and optimized lubrication system enhance durability, enabling stable operation in harsh conditions with dust, vibration, or temperature variations. Adhering to global low-voltage safety standards, it guarantees secure use in voltage-limited sites. Compatible with multiple efficiency classes (IE1 to IE4), it offers flexible configuration to meet energy-saving goals. Widely applied in conveyors, pumps, mixers, and material handling equipment, it balances adaptability and longevity. Backed by SEW’s global service support, it serves as a cost-effective choice for low-voltage helical drive requirements. (300 words)

READ MORE...

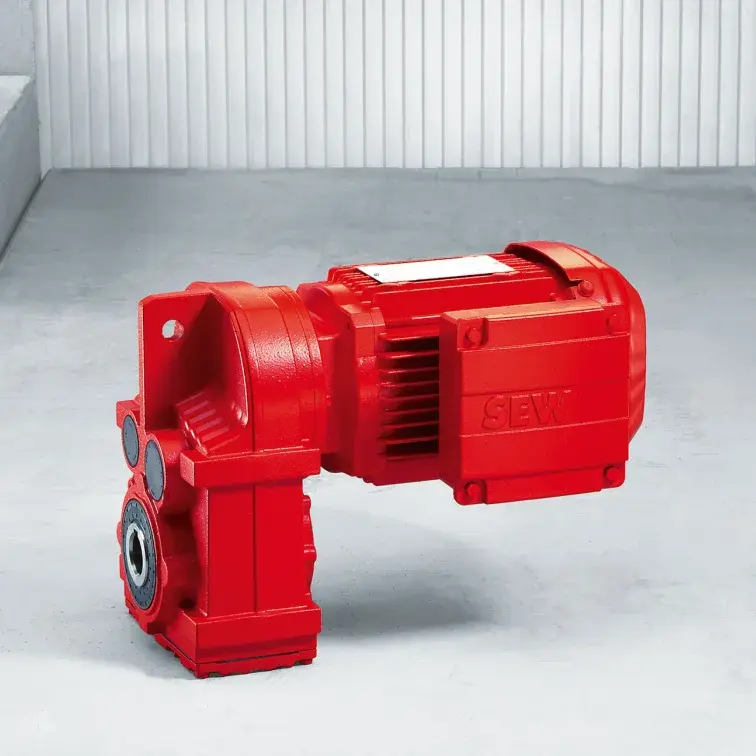

SEW F Series Parallel Shaft Gearmotor low voltage

The SEW F Series Parallel Shaft Gearmotor is a high-efficiency low-voltage drive solution, specialized for industrial applications requiring linear power transmission. Integrating precision parallel shaft gearing with reliable low-voltage motors (including DR/DRE/DRN/DRU series), it delivers consistent torque output, minimal energy loss, and smooth operation, making it ideal for light to heavy-duty tasks. Boasting a compact, space-saving design with coaxial input and output shafts, it facilitates easy integration into tight installations. The robust housing and optimized lubrication system ensure durability in harsh industrial environments, reducing maintenance frequency and extending service life. Adhering to global low-voltage safety standards, it guarantees secure operation in voltage-constrained sites. Compatible with various motor efficiency classes (IE1 to IE4), it offers flexible configuration to meet energy-saving demands. Widely used in conveyors, pumps, fans, and material handling equipment, it balances adaptability, reliability, and cost-effectiveness. Backed by SEW’s global support network, it serves as a versatile choice for low-voltage parallel shaft drive requirements. (300 words)

READ MORE...

SEW K Series Helical Bevel Gearmotor low voltage

The SEW K Series Helical Bevel Gearmotor is a high-performance low-voltage drive solution, engineered for reliable power transmission in diverse industrial scenarios. Integrating precision helical-bevel gearing with efficient low-voltage motors, it delivers smooth torque output, minimal noise, and excellent load-bearing capacity, suitable for both light and medium-duty applications requiring right-angle drives. Compatible with S and S..7p series gear units (sizes 37 to 97), it offers broad configuration flexibility, supporting compound gear setups for ultra-high gear ratios (up to 33,818). Its robust construction ensures durability in harsh environments, while the low-voltage design adheres to global safety standards, enabling safe operation in voltage-constrained sites. Equipped with AM motor adapters, it accommodates motor power ranging from 0.12 to 30 kW, excelling in conveyors, mixers, and material handling equipment. Backed by SEW’s global service, it balances adaptability, reliability, and cost-effectiveness for low-voltage industrial needs. (300 words)

READ MORE...

SEW S Series Helical Worm Gearmotor low voltage

The SEW S Series Helical Worm Gearmotor is a reliable low-voltage drive solution engineered for versatile industrial applications, integrating helical worm gearing with efficient low-voltage motors (DR/DT/DV series). Designed with a compact, robust structure, it delivers excellent torque transmission, quiet operation, and stable performance across light to medium-duty tasks, making it suitable for space-constrained environments. Available in multiple variants including S, SF, SAF, and SHF, it offers flexible configuration with diverse mounting options and shaft designs, adapting to customized system setups. The low-voltage design ensures safe operation in industrial scenarios with voltage constraints, while optimized lubrication and durable components extend service life and reduce maintenance needs. Operating at a standard speed of 1400 rpm, it excels in conveyors, mixers, and material handling equipment. Backed by SEW’s rigorous quality control and global service network, it balances cost-effectiveness, adaptability, and reliability for low-voltage industrial drive requirements. (300 words)

READ MORE...

SEW W Series SPIROPLAN® Right Angle Gearmotor

The SEW W Series SPIROPLAN® Right Angle Gearmotor is a compact, high-efficiency drive solution designed for space-constrained and noise-sensitive industrial applications. Featuring unique SPIROPLAN® gearing with steel-on-steel material combinations and specialized tooth meshing, it achieves wear-free operation, ultra-low noise levels, and mechanical efficiency up to 94%, outperforming traditional worm gear reducers. Its rugged aluminum housing reduces weight while ensuring durability, paired with lifetime lubrication that eliminates maintenance needs and extends service life. The unit supports flexible mounting in any orientation without adjusting lubricant levels, with consistent footprint and shaft heights for both vertical and horizontal setups. Covering gear ratios of 3.2 to 75 and output torques from 12 to 1101 Nm, it suits fractional horsepower tasks. Widely used in packaging conveyors, laboratory mixers, printing equipment, and food/beverage logistics, it balances versatility, cost-effectiveness, and reliable performance for diverse light to medium-duty scenarios. (300 words)

READ MORE...

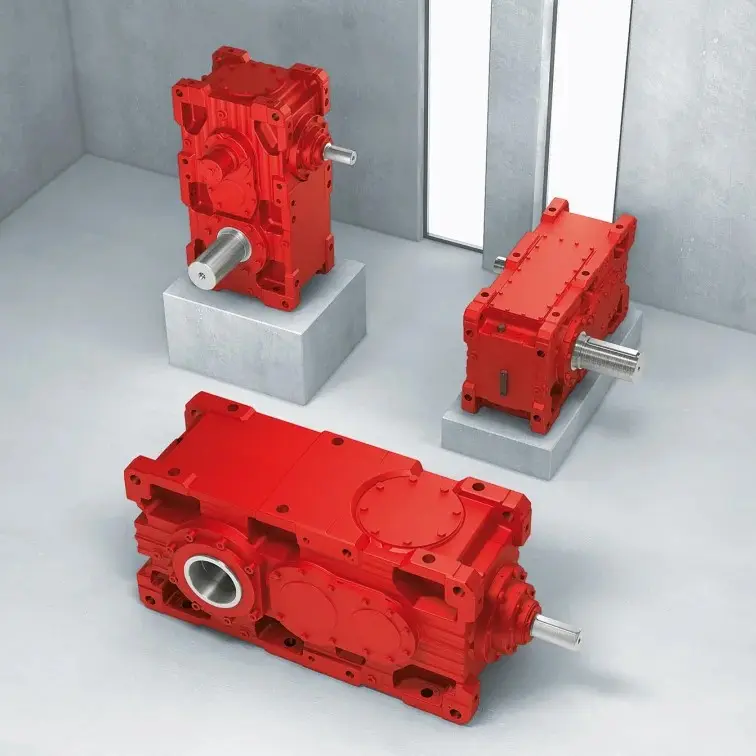

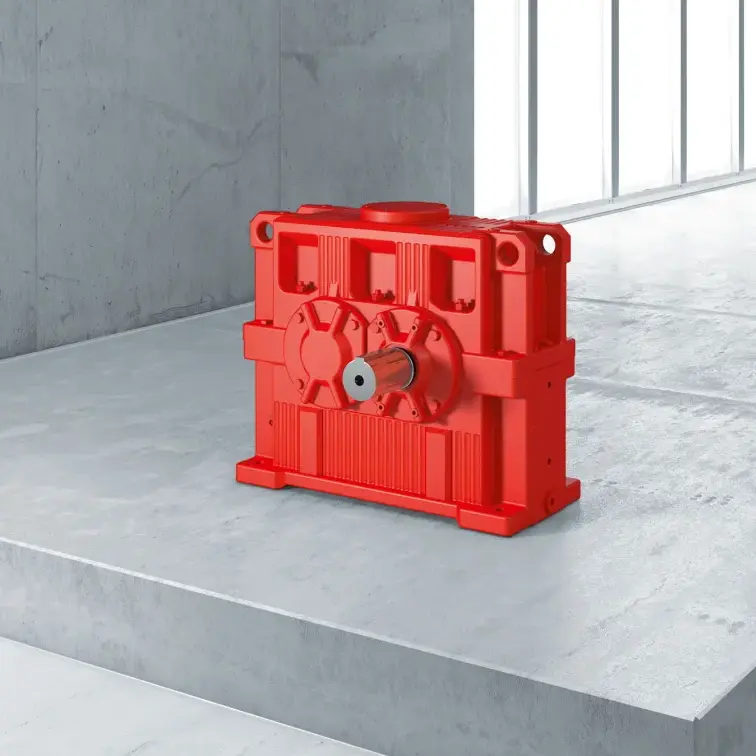

SEW X Series Industrial Gear Unit gearunit gearbox

The SEW X Series Industrial Gear Unit is a rugged, versatile drive platform engineered for demanding heavy-duty applications worldwide. Available as helical (X.F..) and bevel-helical (X.K.., X.T..) variants, it features a robust housing—either single-piece or split—and an axially symmetric, reversible design that enables flexible left/right shaft positions and universal mounting, reducing inventory needs for spare parts. With 23 finely graduated sizes, it covers torque ranges from 6.8 to 475 kNm and gear ratios of 6.3 to 450, avoiding unnecessary oversizing and cutting costs. Equipped with innovative patented cooling systems and modular accessories like motor adapters and backstops, it delivers reliable performance in harsh environments. Widely used in mining, materials handling, and chemical industries for conveyors, mixers, and cranes, it combines global service support with short delivery times for standard versions, ensuring maximum operational availability. (299 words)

READ MORE...

SEW MC series industrial gear units gearunit gearbox

The SEW MC Series Industrial Gear Units are compact, versatile drive solutions tailored for low torque ranges up to 65 kNm and medium gear ratio applications. Designed with a robust one-piece block housing without a parting line, these units offer exceptional rigidity and support horizontal, vertical, and upright mounting, ensuring maximum installation flexibility for diverse machine setups. Available as helical and bevel-helical gear units, they excel at handling high axial and radial loads, thanks to the extended bearing distance (EBD) concept that reinforces internal bearings—eliminating the need for separate agitator bearings in many process engineering scenarios. Optional "drywell" seals prevent oil leakage, minimizing maintenance costs. With a modular design supporting motor adapters, backstops, and belt drives, they suit applications like mixers, bucket elevators, and cooling towers. Backed by SEW’s global service network, the MC Series delivers reliable performance, easy customization, and cost-effectiveness for industrial needs. (299 words)

READ MORE...

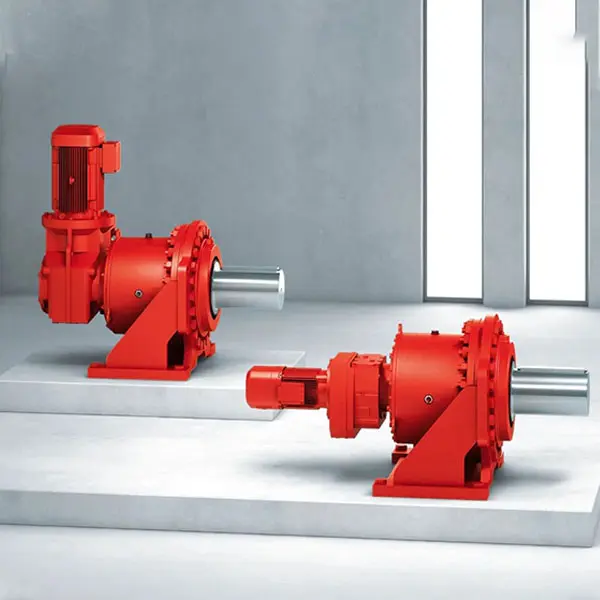

SEW X.e Helical Gear Unit / X Bevel Helical Gear Unit

The SEW X.e Helical Gear Unit and X Bevel Helical Gear Unit represent high-performance drive solutions evolved from the proven X-series, engineered for harsh industrial environments. Retaining the X-series’ invertible housing for flexible left/right shaft positions, the X.e generation boasts enhanced performance with optimized lubrication, advanced sealing, and universal fan cooling systems, reducing operating temperatures and extending maintenance intervals. Covering 23 sizes with torque capacities from 7.2 to 500 kNm and gear ratios of 6.3 to 450, these units offer precise sizing for diverse needs. Their robust modular design supports universal mounting positions and seamless integration with motors, adapters, and accessories. Widely applied in mining, materials handling, and steel industries, they excel at heavy-load tasks like conveyor and crusher drives. Backed by SEW’s global service network, they deliver reliable operation, cost-effectiveness, and easy customization for demanding industrial scenarios. (299 words)

READ MORE...

SEW M1..N Series Helical Gear Unit gearunit gearbox

The SEW M1..N Series Helical Gear Unit is a compact, high-efficiency drive solution designed for general and heavy-duty industrial applications. Engineered with precision-machined helical gears, it delivers smooth power transmission, low operating noise, and excellent load-bearing capacity, making it suitable for continuous operation under varying load conditions. Its robust cast iron housing ensures high rigidity and durability, effectively withstanding vibration and harsh working environments. This series offers flexible configuration options, including 2-, 3-, and 4-stage designs, covering a wide gear ratio range to adapt to diverse speed and torque requirements. It supports multiple mounting positions and seamless integration with motors, enabling customized system setups for industries like materials handling, packaging, and manufacturing. With optimized lubrication systems and low maintenance needs, it reduces operational downtime and costs. Backed by SEW’s reliable quality and global service network, the M1..N Series provides stable performance and long service life for both standard and demanding industrial scenarios. (298 words)

READ MORE...

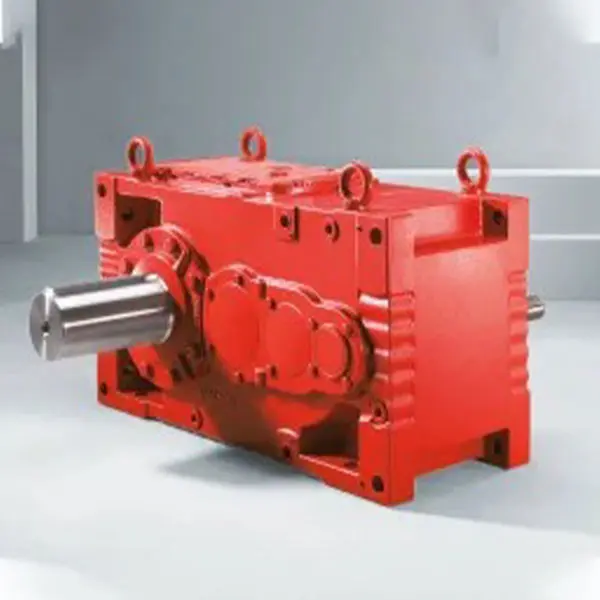

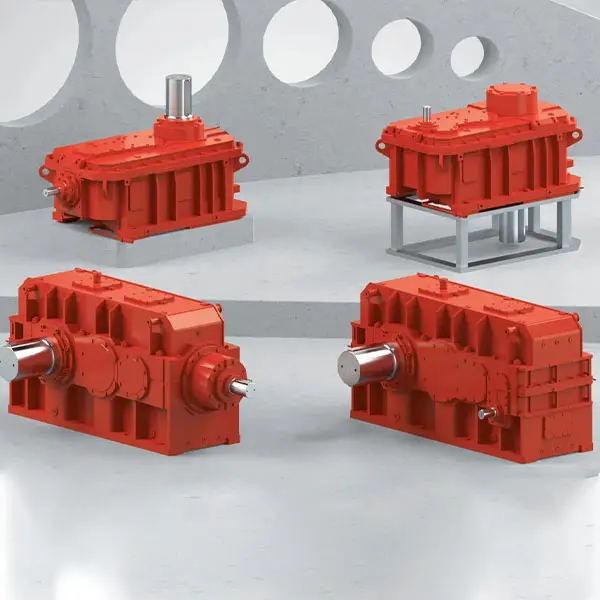

SEW ML..2 Series Helical And Bevel Helical Gear Unit

The SEW ML..2 Series is a heavy-duty helical and bevel-helical gear unit engineered for high-torque industrial applications, boasting a torque range of 1.2 to 6.6 million lb-in. Designed with a robust welded steel housing and split-line structure, it balances exceptional rigidity, reduced weight, and easy maintenance, making it ideal for space-constrained heavy-load scenarios. Its gears, crafted from 18CrNiMo7-6 alloy steel with ISO 6+ precision and 59–61HRC hardness, ensure smooth meshing, low noise, and prolonged service life. Featuring modular design, it supports flexible input/output connections and horizontal mounting, adapting to customized system setups. Equipped with integrated lubrication and cooling systems, it performs reliably in harsh environments like mining, steel, and port industries. Available in fifteen sizes and seven models, it covers diverse needs from bulk material handling to crane drives. Backed by SEW’s global service network, the ML..2 Series delivers consistent efficiency, durability, and cost-effectiveness for demanding heavy-industry requirements. (299 words)

READ MORE...

Unlocking Efficiency: The Comprehensive Guide to YE3 Low Power Motors and Their Industrial Applications

YE3 low power motors represent a leap forward in energy-efficient industrial technology, designed to reduce operational costs and environmental impact. This guide explores their benefits, key features, and how to integrate them with components like variable frequency drives and gearboxes for optimal performance in various sectors.

READ MORE...

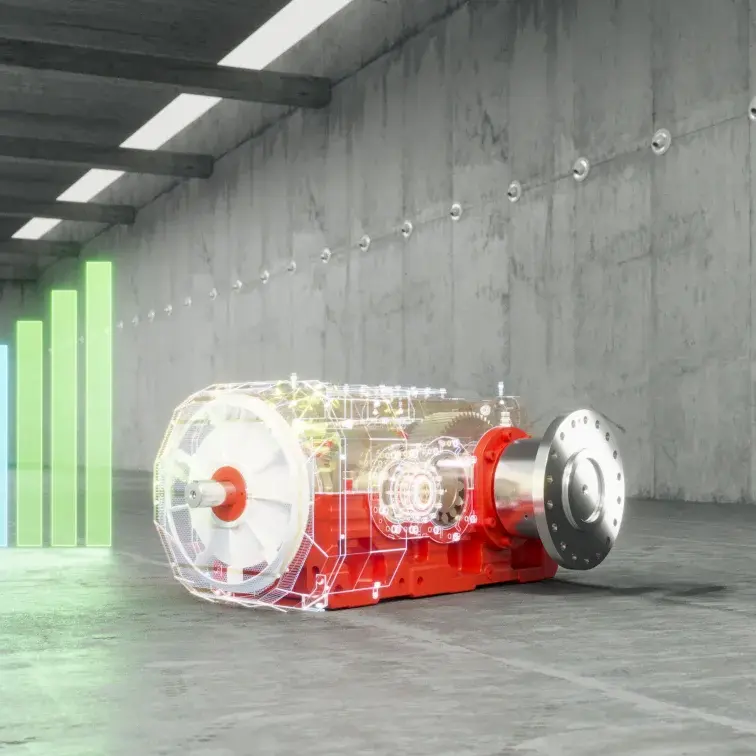

SEW P Series Planetary Gear Unit gearbox

The SEW P Series Planetary Gear Unit is a high-torque, compact drive solution designed for heavy-duty industrial applications. Engineered with a robust planetary gear structure, it delivers exceptional power density, making it ideal for scenarios where space is limited but high performance is required. This series covers a wide nominal torque range and supports flexible gear ratio configurations, adapting to diverse speed and load demands across industries. Featuring a modular design, it enables easy integration with motors, adapters, and auxiliary components, supporting multiple mounting positions for customized system setups. Precision-machined gears and a durable housing ensure low noise, high wear resistance, and long service life, even in harsh operating environments with dust, vibration, or extreme temperatures. Widely applied in materials handling, mining, and construction machinery, it excels at heavy-load transmission tasks. Backed by SEW’s reliable quality control and global service network, the P Series offers stable operation, easy maintenance, and cost-effectiveness for demanding industrial drive needs.

READ MORE...