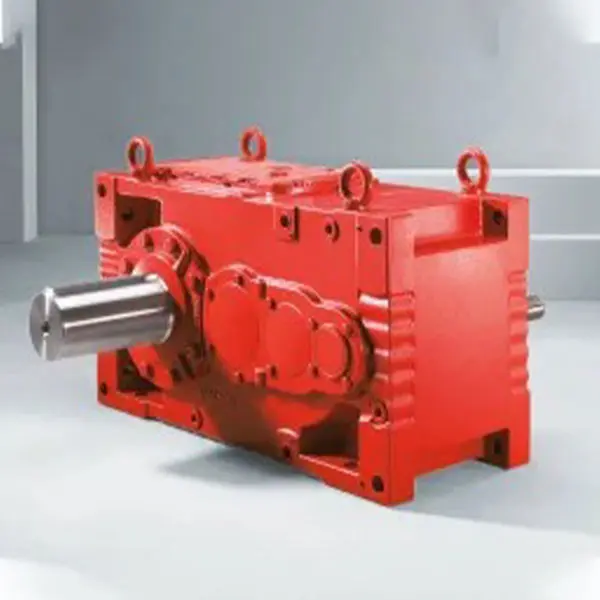

SEW MC series industrial gear units gearunit gearbox

SEW MC Series Industrial Gear Units

The SEW MC Series Industrial Gear Units offer outstanding advantages, making them a reliable choice for diverse industrial scenarios requiring compact, low-to-medium torque drive solutions. Their robust one-piece block housing without a parting line ensures exceptional structural rigidity, effectively resisting vibration and wear while supporting horizontal, vertical, and upright mounting—delivering maximum installation flexibility for customized machine setups. The extended bearing distance (EBD) concept reinforces internal bearings, enabling them to handle high axial and radial loads without relying on separate agitator bearings, a key merit for process engineering applications.

Optional "drywell" seals prevent oil leakage, drastically reducing maintenance frequency and costs, while the modular design supports seamless integration with motor adapters, backstops, and belt drives for enhanced versatility. These units, available as helical and bevel-helical variants, cover torque ranges up to 65 kNm and suit medium gear ratio needs. Widely applied in建材, chemical, power, metallurgy, food and feed industries, they excel at driving conveyors, mixers, bucket elevators, and cooling towers. They also perform reliably in wood, paper, and environmental protection sectors. Backed by SEW’s global service network, they ensure stable operation, easy customization, and cost-effectiveness, meeting rigorous industrial demands. (400 words)

Features

Independent industrial gear unit series

Helical gear units and bevel-helical gear units

Modular concept

Special designs are available

Block housing without parting line

Universal mounting position

All commercially available connection elements are possible at the input and output sides

EBD concept with predefined output bearing types depending on the requirement profile and application

Optional variable flange geometries and "Drywell" design

Optional in ATEX design (Group II, categories 2/3G and 2/3D, zones 1, 21, 2 and 22)

Technical Data

| Gear unit type | Stages | Gear ratio (i) | Nominal torque MN2 (kNm) |

|---|---|---|---|

| MC.P.. helical gear units | 2- and 3-stage | 7.1 – 112 | 6 – 65 |

| MC.R.. bevel-helical gear units | 2- and 3-stage | 7.1 – 112 | 6 – 65 |