SEW X.e Helical Gear Unit / X Bevel Helical Gear Unit

SEW X.e Helical Gear Unit / X Bevel Helical Gear Unit

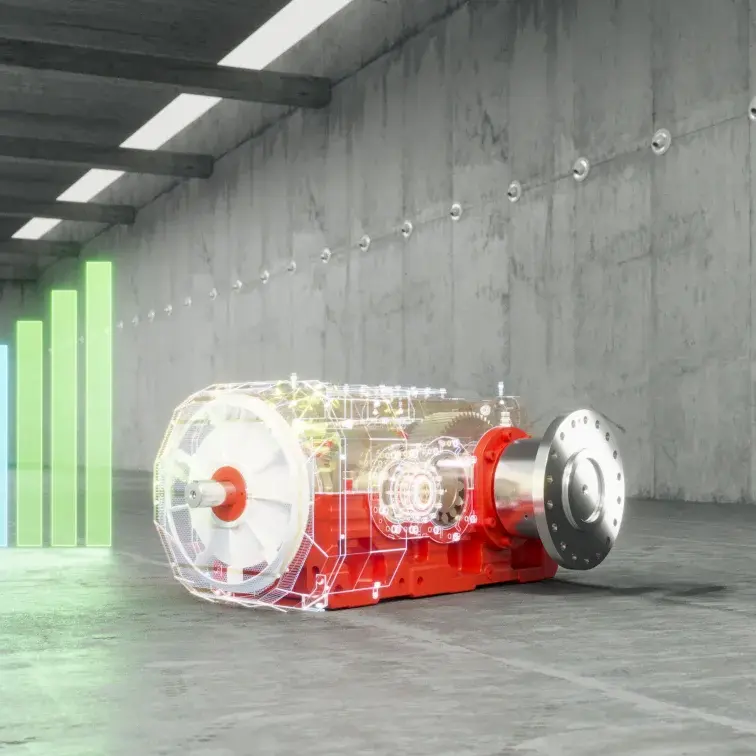

The SEW X.e Helical Gear Unit and X Bevel Helical Gear Unit offer outstanding advantages tailored for harsh industrial environments, making them reliable choices for heavy-duty drive tasks. Evolved from the proven X-series, they retain the invertible housing design for flexible left/right shaft positions, while the X.e generation enhances performance with optimized lubrication systems, advanced sealing technology, and universal fan cooling—effectively lowering operating temperatures, minimizing wear, and extending maintenance intervals, thus reducing downtime and operational costs.

Boasting robust construction, these units deliver exceptional durability and load-bearing capacity, covering 23 sizes with torque ranges of 7.2 to 500 kNm and gear ratios of 6.3 to 450 for precise adaptation to diverse speed and load demands. Their modular design supports universal mounting positions and seamless integration with motors, adapters, and accessories, boosting installation flexibility for customized system setups. Widely applied in mining, materials handling, and steel industries, they excel at heavy-load tasks such as conveyor, crusher, and mixer drives. Backed by SEW’s global service network, they ensure stable operation, easy maintenance, and cost-effectiveness, catering to the rigorous requirements of demanding industrial scenarios. (400 words)

description

One standard product – numerous possibilities

For operators or original equipment manufacturers of machines and plants, it is crucial that the drives used there are robust, reliable and easy to maintain. The industrial gear units of the X..e series efficiently meet these requirements.

The intelligent, universal gear unit concept impresses with its fine size graduation, high installation variability and the large number of additional modular features and options such as motor adapters, backstop, various sealing and shaft systems, and many more. The wide ratio range of 6.3 - 450 and the robust design make the All-Rounder the right choice in many industries and applications. Whether crane, conveyor belt or mixer - with the X..e series and the industry know-how of SEW-EURODRIVE, you are opting for maximum availability and a reliable partner. And if our modular system does not have the right solution for you, we will customise our gear units for you.

Technical Data

| Gear unit design | Stages | Gear ratio i | Nominal torque MN2 (kNm) |

|---|---|---|---|

| Helical gear unit X.F.100e – X.F.320e | 2 to 4 stages | 6.3 – 450 | 7.2 – 500 |

| Bevel-helical gear unit X.K.100e – X.K.320e | 2 to 4 stages | 6.3 – 450 | 7.2 – 500 |

| Bevel-helical gear unit* X.T.100e – X.T.250e | 3 and 4 stages | 12.5 – 450 | 7.2 – 185 |