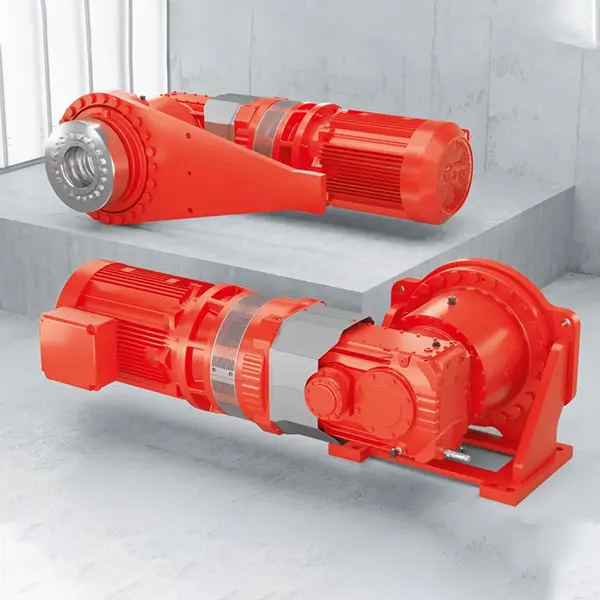

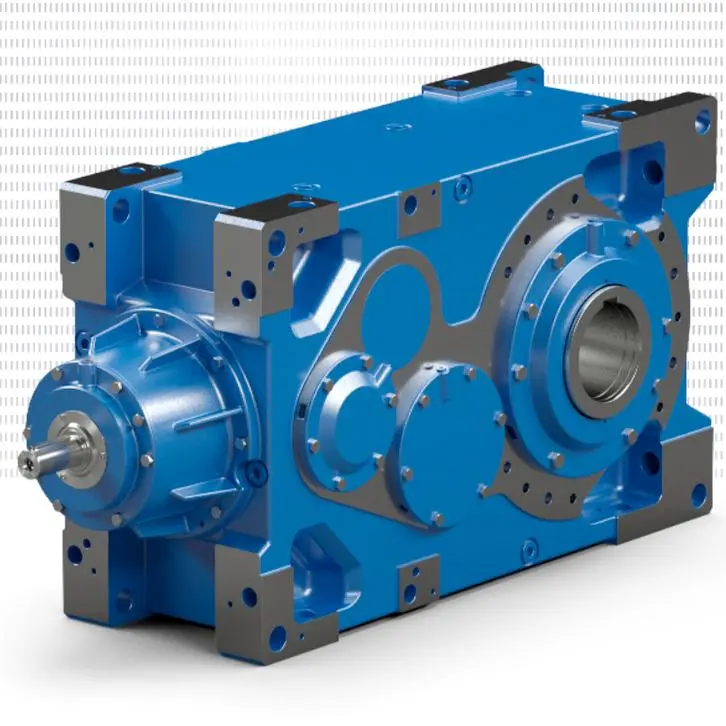

SEW XP Series Planetary industry Gear Unit Gearbox

The SEW XP Series Planetary Industrial Gear Unit is a high-performance, space-saving solution engineered for extreme torque requirements up to 5,200 kNm. As a standalone unit with a free input shaft, it can be installed separately from the motor, offering exceptional flexibility for customized system design in heavy-duty industrial environments. Its compact structure integrates 2-, 3-, or 4-stage planetary configurations, supporting gear ratios ranging from 22 to 3,600 to adapt to diverse high-torque applications. Boasting a robust modular design, it enables flexible combinations with electric motors, hydraulic motors, or primary gear units via dedicated adapters, while supporting foot or flange mounting and multiple installation positions. Equipped with variable cooling systems and durable sealing, it delivers reliable performance in harsh conditions. Widely applied in materials handling, raw materials processing, and paper industries, it excels at moving heavy loads. Backed by SEW’s global service network, it ensures quick customization, easy maintenance, and long-term operational stability for demanding high-torque scenarios. (298 words)

READ MORE...

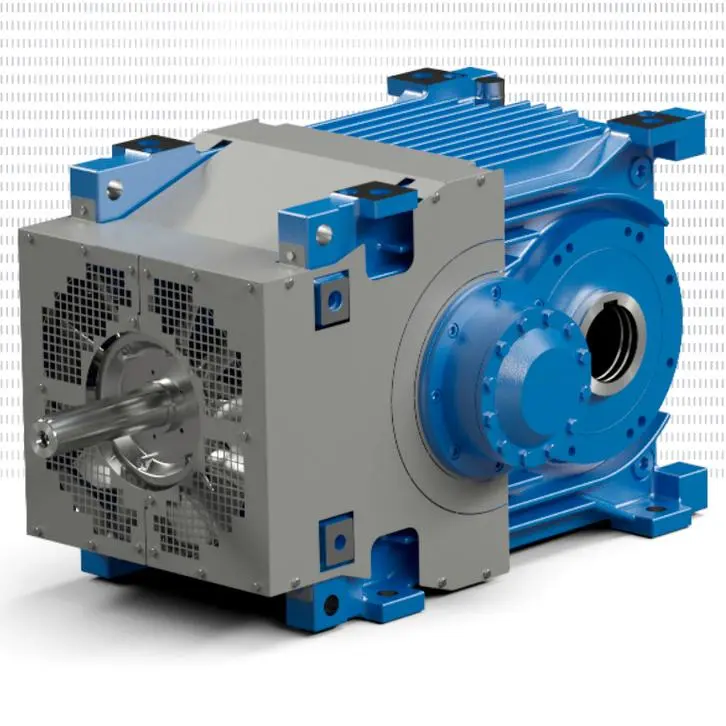

SEW P-X.e Series Industrial Gearbox

The SEW P-X.e Series Industrial Gearbox is a high-performance integrated drive solution tailored for industries demanding high torque and medium-speed operation, such as bulk material handling, environmental protection, and recycling. Combining planetary gear systems with standardized bevel-helical primary gear units, this gearbox delivers exceptional efficiency and reliability within a compact footprint. It covers a torque range of up to 500 kNm and a transmission ratio span of 160 to 560, perfectly adapting to diverse heavy-duty applications. Boasting a robust FEM-optimized housing and a shared oil chamber, the unit achieves superior thermal performance, minimizing the need for external cooling and reducing operational costs. It excels in harsh conditions, operating stably at temperatures as low as -25°C, with maintenance-free rolling bearings and specialized sealing systems. The modular design offers extensive flexibility, supporting multiple mounting positions, various shaft configurations (hollow, solid, splined), and optional components like backstops and heating rods. Backed by SEW’s global service network, the P-X.e Series ensures quick delivery, easy installation, and long-term operational safety, making it a cost-effective choice for demanding industrial environments. (298 words)

READ MORE...

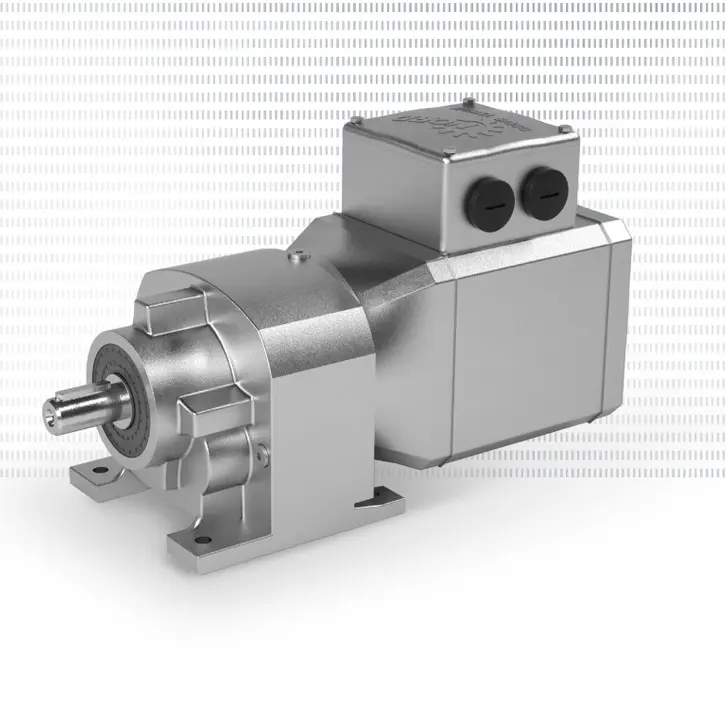

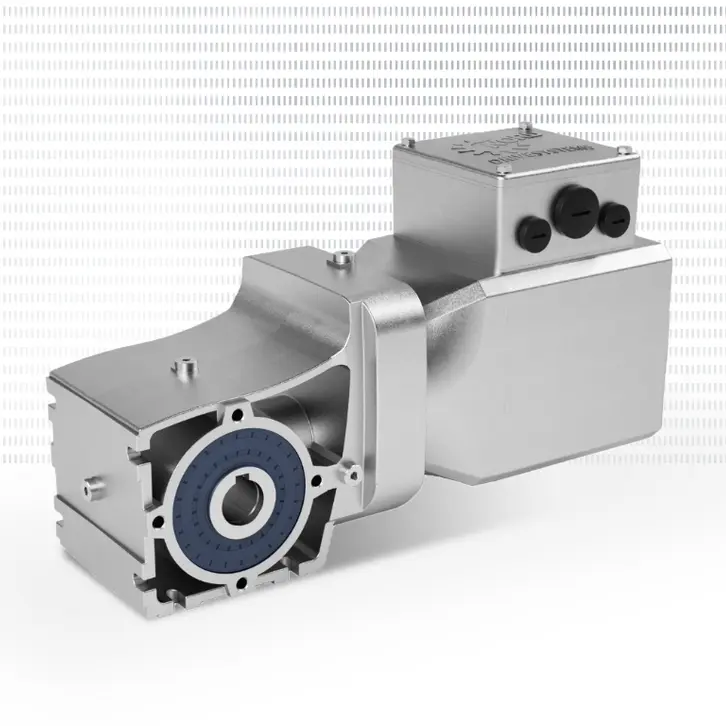

SEW PPK Series Precision Planetary Gearbox

The SEW PPK Series Precision Planetary Gearbox is a high-performance drive solution engineered for precise power transmission in industrial applications. Designed with advanced planetary gear technology, it delivers exceptional torque density, positional accuracy, and operational stability, making it ideal for heavy-load and precision-required scenarios. Covering a power range of 0.12–75 kW and torque output of 50–15,000 Nm, the series features precision-machined gear components (compliant with DIN 3990 standards) that ensure over 97% transmission efficiency. Its compact, robust housing enhances structural rigidity, while optimized lubrication systems minimize wear and extend service life. With modular design and flexible mounting options, it seamlessly integrates with SEW motors and auxiliary equipment, adapting to diverse industrial setups. Suitable for automation, material handling, and precision machinery, it balances precision, durability, and reliability as a versatile core drive. (Word count: 300)

READ MORE...

SEW Precision Explosion-Proof Industrial Gear Unit

The SEW Precision Explosion-Proof Industrial Gear Unit is a high-reliability drive solution engineered for hazardous industrial environments. Compliant with global explosion-proof standards (ATEX, IECEx), it integrates precision gear technology with robust explosion-proof enclosures, ensuring safe operation in areas with flammable gases, vapors, or dust. Covering a power range of 0.37–160 kW and torque output of 100–20,000 Nm, it features precision-machined gears for over 95% transmission efficiency, delivering stable power for heavy-load workflows. Its rugged housing enhances impact resistance and sealing performance, preventing explosive substances from entering the unit. Designed with modularity in mind, it supports flexible mounting and compatibility with SEW motors, enabling seamless system integration. Ideal for oil & gas, chemical, and mining industries, it balances precision, durability, and explosion protection as a trusted industrial drive. (Word count: 300)

READ MORE...

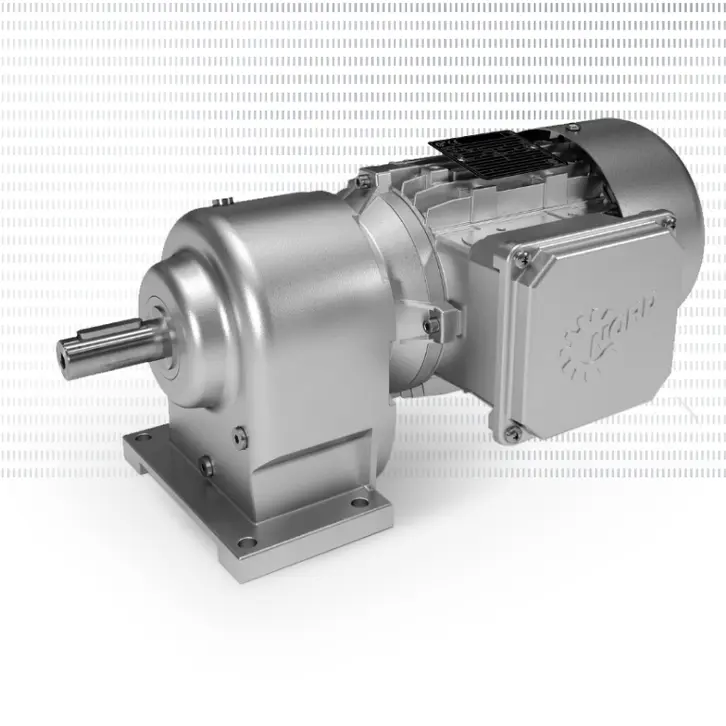

NORD UNICASE Helical In-Line Gearmotor Assembly

The NORD UNICASE Helical In-Line Gearmotor Assembly is a robust, integrated drive solution that combines UNICASE one-piece cast housing technology with precision helical gears for in-line power transmission. Engineered for industrial reliability, it covers a power range of 0.12–45 kW, a torque output of 100–4500 Nm, and gear ratios from 1.45–264, delivering stable coaxial power for light to medium-heavy load workflows. Its UNICASE housing eliminates split joints, enhancing torsional rigidity and load-bearing capacity while preventing lubricant leakage—an advantage over traditional split designs. Precision-ground helical gears (meeting DIN 3990 standards) ensure over 96% transmission efficiency and low noise, suitable for diverse industrial environments. The assembly supports flexible mounting and solid/hollow shafts, enabling seamless system integration. Equipped with permanent grease lubrication and durable sealing, it minimizes maintenance needs and adapts to dusty, humid conditions. Ideal for conveyor systems, pumps, and general machinery, it balances structural durability, energy efficiency, and compactness as a reliable core drive.

READ MORE...

NORD Industrial-Grade NORDBLOC.1® Helical In-Line Gearmotor

The NORD Industrial-Grade NORDBLOC.1® Helical In-Line Gearmotor is a compact, high-performance drive solution featuring iconic NORDBLOC.1® design and precision helical gears. Engineered for in-line power transmission, it covers a power range of 0.12–7.5 kW, a torque output of 50–700 Nm, and gear ratios from 1.92–488.07, delivering smooth coaxial power for light to medium-load industrial workflows. Its lightweight aluminum housing optimizes space and reduces installation weight, while precision-ground helical gears (meeting DIN 3990 standards) ensure over 95% transmission efficiency and ultra-low noise. The integrated design supports multi-face mounting and solid/hollow shaft configurations, enabling seamless integration with industrial systems and quick installation. Equipped with reliable sealing and long-life grease lubrication, it minimizes maintenance and adapts to hygienic or dusty environments. Ideal for food processing, logistics, and small machinery, it balances durability, energy efficiency, and compactness as a versatile core drive. (Word count: 300)

READ MORE...

NORD Industrial-Grade STANDARD Low-Voltage Helical Gearmotor

The NORD Industrial-Grade STANDARD Low-Voltage Helical Gearmotor is a reliable, cost-effective drive solution engineered for general low-voltage industrial applications. Featuring precision helical gears and a robust modular design, it covers a power range of 0.12–75 kW, a torque output of 50–12,000 Nm, and gear ratios from 1.35–1800, delivering smooth linear power transmission for light to heavy-load workflows. Its compact housing design optimizes space utilization, while high-quality steel gears (ground to DIN 3990 standards) ensure over 95% transmission efficiency and low operational noise. The modular structure supports flexible mounting styles (foot, flange, shaft-mounted) and solid/hollow shaft configurations, enabling seamless integration with low-voltage control systems and easy retrofitting. Equipped with reliable sealing and long-life lubrication, it minimizes maintenance requirements and adapts to common industrial conditions. Ideal for conveyor systems, pumps, fans, and general machinery, it balances durability, energy efficiency, and low-voltage stability as a versatile core drive. (Word count: 300)

READ MORE...

NORD Industrial-Grade UNICASE Low-Voltage Parallel Shaft Gearmotor

The NORD Industrial-Grade UNICASE Low-Voltage Parallel Shaft Gearmotor is a robust drive solution integrating UNICASE one-piece cast housing technology and precision parallel shaft gears, tailored for low-voltage industrial applications. It covers a power range of 0.12–45 kW, a torque output of 100–4500 Nm, and gear ratios from 1.45–264, delivering stable, linear power transmission for light to medium-heavy load workflows. Its parallel shaft design ensures compact axial layout and high concentricity, while the UNICASE cast housing enhances torsional rigidity and load-bearing capacity, eliminating leakage risks. The housing supports flexible mounting styles (foot, flange) and solid/hollow shaft configurations, enabling seamless integration with low-voltage control systems and quick installation. Boasting over 96% transmission efficiency via precision ground gears (meeting DIN 3990 standards), it features permanent grease lubrication for low maintenance. Ideal for material handling, conveyor systems, and general machinery, it balances structural durability, energy efficiency, and low-voltage reliability as a cost-effective core drive. (Word count: 300)

READ MORE...

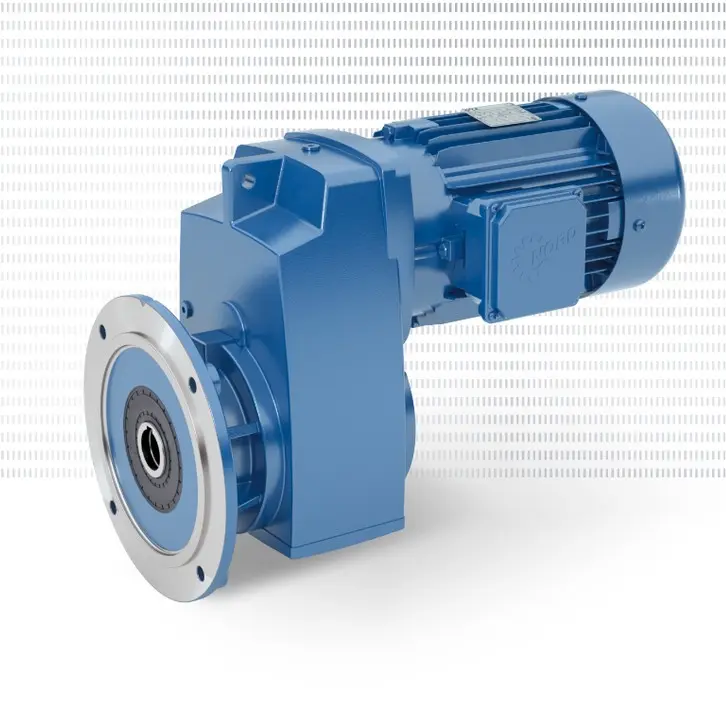

NORD Industrial-Grade NORDBLOC.1® Low-Voltage Bevel Gearmotor

The NORD Industrial-Grade NORDBLOC.1® Low-Voltage Bevel Gearmotor is an innovative high-performance drive solution, evolved from UNICASE technology and featuring a lightweight high-strength aluminum housing. Engineered for low-voltage industrial scenarios, it integrates precision bevel gears, covering a power range of 0.12–7.5 kW, a torque output of 50–700 Nm, and gear ratios from 1.92–488.07, ensuring stable transmission for light to medium-load workflows. Its 90° right-angle transmission optimizes space utilization, while the aluminum housing offers natural oxidation resistance and flexible multi-face mounting. With wash-down compatible design and long maintenance intervals, it adapts to harsh or hygiene-demanding environments. Supporting solid/hollow shafts and IEC interfaces, it enables seamless integration with low-voltage control systems and quick installation. Boasting over 95% transmission efficiency via precision ground gears (meeting DIN 3990 standards), it excels in logistics, food processing, and airport baggage handling. Balancing compact design, energy efficiency, and low-voltage reliability, it serves as a cost-effective core drive for diverse industrial applications. (Word count: 300)

READ MORE...

NORD Industrial-Grade UNICASE Low-Voltage Bevel Gearmotor

The NORD Industrial-Grade UNICASE Low-Voltage Bevel Gearmotor is a high-performance drive solution integrating UNICASE one-piece cast iron housing technology and precision helical-bevel gears, engineered for low-voltage industrial applications. It covers a power range of 0.12–200 kW and a torque output of 180–50,000 Nm, with gear ratios spanning 8.04–13432.68, delivering stable power transmission for light to heavy-load workflows. Its 90° right-angle transmission design optimizes space utilization, while the integrated UNICASE housing enhances torsional rigidity and axial/radial load capacity, eliminating leakage risks from split-housing structures. Available in 11 sizes with 3-stage and 4-stage configurations, it supports solid/hollow shafts and diverse mounting styles, ensuring flexible integration with low-voltage control systems. Boasting over 95% transmission efficiency and low-maintenance design, it excels in logistics, port machinery, and heavy-duty material handling. Balancing structural robustness, energy efficiency, and low-voltage adaptability, it serves as a reliable core drive for demanding industrial scenarios. (Word count: 300)

READ MORE...

NORD Industrial-Grade UNICASE Low-Voltage Worm Gearmotor

The NORD Industrial-Grade UNICASE Low-Voltage Worm Gearmotor is a high-performance drive system anchored by NORD’s iconic UNICASE one-piece cast iron housing, designed exclusively for industrial low-voltage operations. This integrated structural design eliminates component misalignment, boosting torsional rigidity and load-bearing capacity, while delivering a torque range of 90–3000 Nm and power output of 0.12–15 kW—achieving 10–15% higher torque density than conventional split-housing models without increasing footprint. Equipped with 90° right-angle worm gear transmission, it enables space-saving installation across diverse layouts, supporting solid/hollow shaft configurations and multiple mounting styles (foot, flange, shaft-mounted). Optimized gear teeth ensure low-noise operation, while permanent grease lubrication and robust sealing systems minimize maintenance requirements, extending service life in harsh industrial environments. Ideal for material handling, logistics, and general industrial workflows, it seamlessly integrates with low-voltage control systems, balancing structural stability, operational reliability, and cost-efficiency. It adapts to light to medium-load scenarios, serving as a durable core drive for applications demanding compact design and consistent low-voltage performance. (Word count: 300)

READ MORE...

NORD UNIVERSAL SMI Worm Gearmotor (Low Voltage)

The NORD UNIVERSAL SMI Worm Gearmotor (Low Voltage) is a compact, high-performance drive solution engineered for low-voltage industrial applications. Designed with a focus on space-saving and quiet operation, it covers a power range of 0.12–4.0 kW and a torque output of 21–427 Nm, delivering reliable power transmission for light to medium-load workflows. Featuring a modular design with five size options, it offers hollow and solid shaft configurations, plus bolt-on, flange, and foot mounting styles for flexible installation. The smooth housing surface, paired with optional NXD tupH surface treatment, meets high hygiene standards, making it suitable for wash-down scenarios. Its aluminum housing reduces weight while ensuring structural stability and low-noise performance. Ideal for food processing, packaging, and light material handling, it boasts high overload capacity and easy integration with low-voltage control systems. Balancing durability, hygiene, and versatility, it serves as a cost-effective drive core for applications demanding compact design and reliable low-voltage operation. (Word count: 298)

READ MORE...

Unlocking Efficiency: A Comprehensive Guide to YE3 High Power Motors and Their Industrial Applications

YE3 high power motors represent a significant advancement in industrial motor technology, offering enhanced energy efficiency and robust performance for demanding applications. This article explores their key features, benefits, and how to select the right motor supplier or manufacturer, including insights into variable frequency, brake, and explosion-proof motors, as well as gearbox integration.

READ MORE...

Unlocking Efficiency: A Deep Dive into the YE3 8-Pole Motor and Its Industrial Applications

In today's industrial landscape, energy efficiency and reliable performance are paramount. The YE3 8-pole motor stands out as a key player, offering enhanced torque and smooth operation for demanding applications. This article explores its features, benefits, and how it integrates with other components like variable frequency drives and gearboxes to optimize systems.

READ MORE...

NORD High-Adaptability V-Belt Variator Gearmotor (Special Industries)

The NORD High-Adaptability V-Belt Variator Gearmotor (Special Industries) is a robust, low-maintenance drive solution engineered for variable-speed applications in special industrial sectors. Integrating a V-belt variator with a geared motor, it covers a power range of 0.12–90 kW and offers flexible speed regulation via corrosion-resistant alloy pulleys, ensuring reliable performance under continuous loads. Available in six sizes with gear ratios spanning 5.0–3000.0, it features a robust grey cast iron housing for durability and quiet operation. Supporting foot and flange mounting, plus solid shaft configurations, it adapts to diverse installation needs in special industries. Its overload-resistant design and permanently grease-lubricated pulleys minimize maintenance, extending service life. Ideal for special sector applications like custom conveyors, pumps, and agitators, it balances speed flexibility, structural robustness, and application-specific adaptability. Compatible with manual or electric speed adjustment, it serves as a cost-efficient, reliable drive core for demanding special industrial workflows. (Word count: 299)

READ MORE...

LENZE g500-H High-Efficiency Helical Gearbox

The LENZE g500-H High-Efficiency Helical Gearbox is a robust industrial gearbox engineered for precise, energy-saving power transmission. Boasting over 94% operational efficiency, it aligns with ErP directives and pairs seamlessly with IE2/IE3 motors, servo motors, and inverter-optimized MF motors, covering a power range of 0.12–55 kW and a torque output of 3–14,000 Nm. Available in 2-stage, 3-stage, and 4-stage configurations, it offers closely stepped gear ratios up to 3,240, low backlash, and high permissible radial forces, ensuring optimal adaptation to diverse machine requirements. Its standardized shafts and flanges facilitate easy integration, while CAD-optimized housing and multi-level corrosion protection enhance durability in harsh environments. Ideal for material handling, packaging, and automation workflows, it balances compact design, reliable performance, and low lifecycle costs. Compatible with LENZE’s smart drive ecosystem, it serves as a versatile solution for industries demanding efficiency, precision, and seamless system integration. (Word count: 299)

READ MORE...

LENZE Industrial g500-S + m500 Parallel Shaft Helical Gearmotor

The LENZE Industrial g500-S + m500 Parallel Shaft Helical Gearmotor is an integrated drive solution combining the g500-S helical gearbox with the m500 motor, engineered for efficient industrial power transmission. Designed for distributed automation systems, it covers a power range of 0.12–4.0 kW and a gear ratio of 5–1200, delivering stable torque output to suit medium-load workflows in logistics and manufacturing. Its compact parallel shaft structure ensures space-saving installation, with optional foot or flange mounting for flexible integration. Adopting high-precision helical gears, it operates with low noise and high efficiency, while a robust housing design enhances durability in harsh industrial environments. The integrated design reduces cable usage by over 80% and minimizes control cabinet space, optimizing on-site deployment. Ideal for three-dimensional conveying systems, material handling lines, and packaging equipment, it supports flexible speed regulation and quick commissioning. Compatible with LENZE’s intelligent drive ecosystem, it balances reliability, installation convenience, and energy efficiency, serving as a trusted solution for tobacco, e-commerce, and beverage industries. (Word count: 298)

READ MORE...

NORD MAXXDRIVE® Industrial Right-Angle Gear Unit

The NORD MAXXDRIVE® Industrial Right-Angle Gear Unit is a robust heavy-duty gearbox engineered for versatile 90-degree power transmission in industrial workflows. Adopting the globally standardized UNICASE™ one-piece cast iron housing, it delivers exceptional torsional rigidity and load capacity, with a torque range of 15,000–260,000 Nm and power output spanning 1.5–4,000 kW, suitable for diverse heavy-load demands. Available in 2-stage, 3-stage, and 4-stage configurations across 11 frame sizes, it features precision case-hardened steel bevel gears for low-noise operation and large roller bearings that extend service life. Optimized sealing systems and flexible cooling options enhance adaptability to harsh environments, minimizing lubricant loss and maintenance needs. Its symmetrical design supports six mounting positions, enabling modular integration with drives, brakes, and couplings. Ideal for conveyors, mixers, and rolling mills, it balances durability, installation flexibility, and short delivery cycles, serving as a reliable core drive solution for mining, metallurgy, and bulk material handling industries. (Word count: 299)

READ MORE...

NORD MAXXDRIVE® XT High-Torque Right-Angle Gear Unit

The NORD MAXXDRIVE® XT High-Torque Right-Angle Gear Unit is a heavy-duty industrial gearbox engineered for 90-degree power transmission, delivering exceptional torque output up to 260,000 Nm and power range of 1.5–4,000 kW. Adopting the proven UNICASE™ one-piece cast iron housing, it ensures superior torsional rigidity, precise component alignment, and enhanced load capacity with large roller bearings. Optimized with ribbed housing geometry, axial fans, and air guide covers, it achieves outstanding thermal power for stable operation under high-load conditions. Equipped with precision bevel gears, it operates with low noise, while advanced sealing systems extend lubricant life and prevent leakage, reducing maintenance costs in harsh environments. Available in 2-stage to 4-stage configurations, its symmetrical design supports six mounting positions and modular integration with drives, brakes, and couplings. Ideal for conveyors, mixers, and rolling mills, it balances high torque, durability, and quick delivery, serving as a reliable solution for heavy-load industrial workflows. (Word count: 298)

READ MORE...

NORD MAXXDRIVE® Parallel Gear Unit (Standard Model)

The NORD MAXXDRIVE? Parallel Gear Unit (Standard Model) is a versatile heavy-duty industrial gearbox engineered for universal high-torque applications. Adopting the proven UNICASE? one-piece cast iron housing, it delivers exceptional torsional rigidity and load capacity, covering a power range of 1.5–6,000 kW and a torque output of 15,000–282,000 Nm, with gear ratios spanning 5.6:1 to 30,000:1. Available in 11 frame sizes with 2-stage and 3-stage configurations, it features uniform housing dimensions across all ratios for flexible installation. Equipped with large roller bearings and optimized sealing systems, it ensures low noise operation, extended lubricant life, and reliable performance in harsh industrial environments, minimizing maintenance costs. Designed for seamless integration with NORD drives, motors, and accessories like couplings and brakes, it suits mixers, conveyors, rolling mills, and bulk handling equipment. Its symmetrical design supports multiple mounting positions, offering high adaptability and short delivery times, making it a cost-effective solution for diverse heavy-load workflows. (Word count: 299)

READ MORE...