SEW PPK Series Precision Planetary Gearbox

Overview of SEW PPK Series Precision Planetary Gearbox

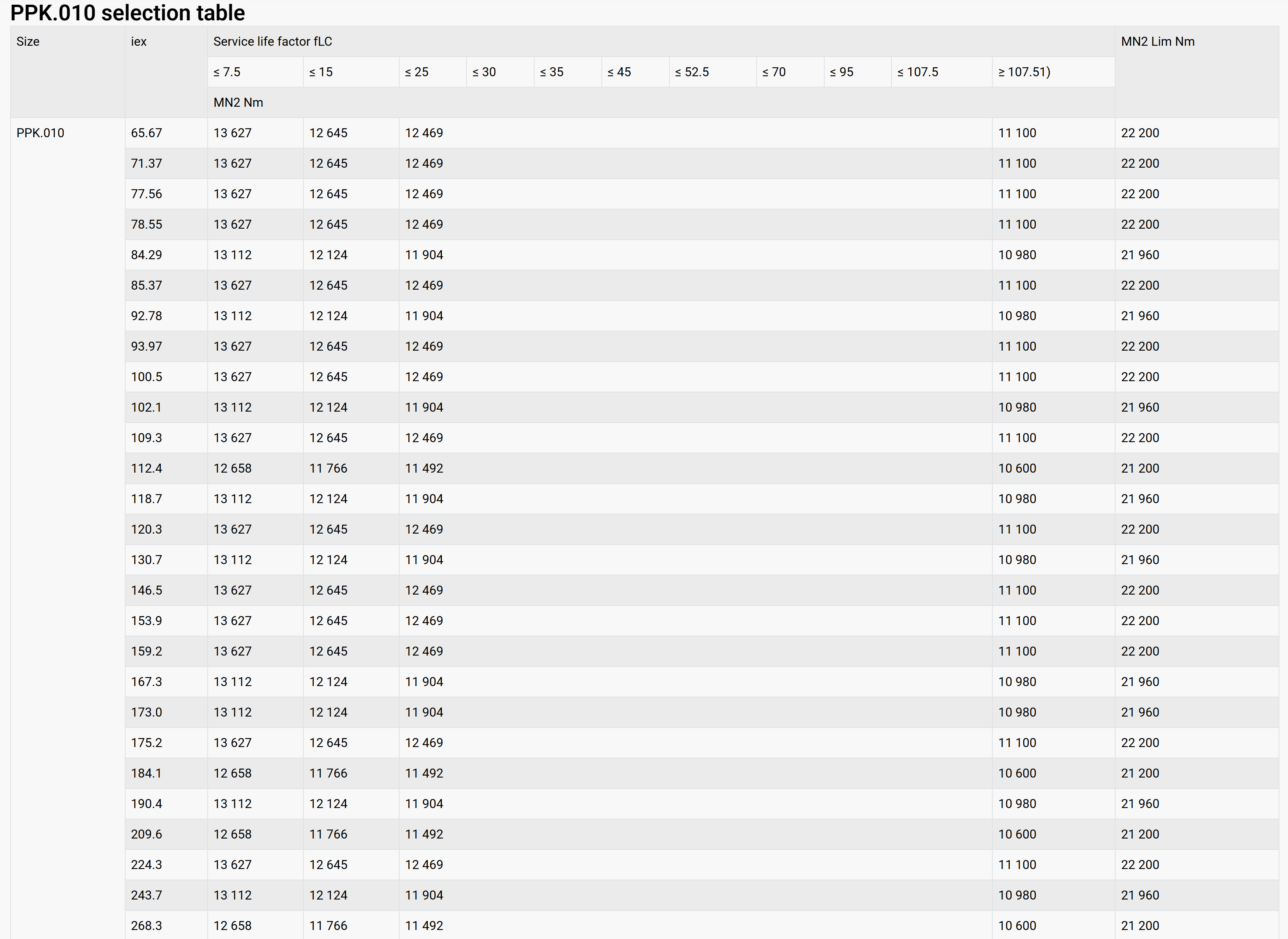

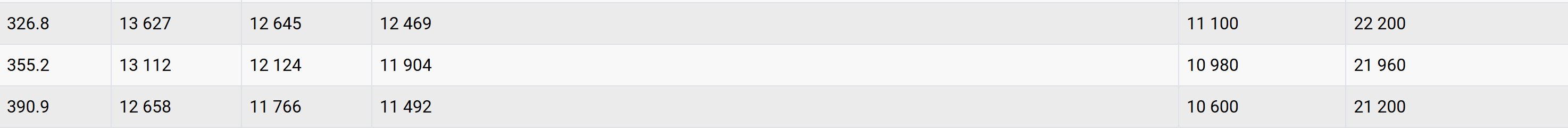

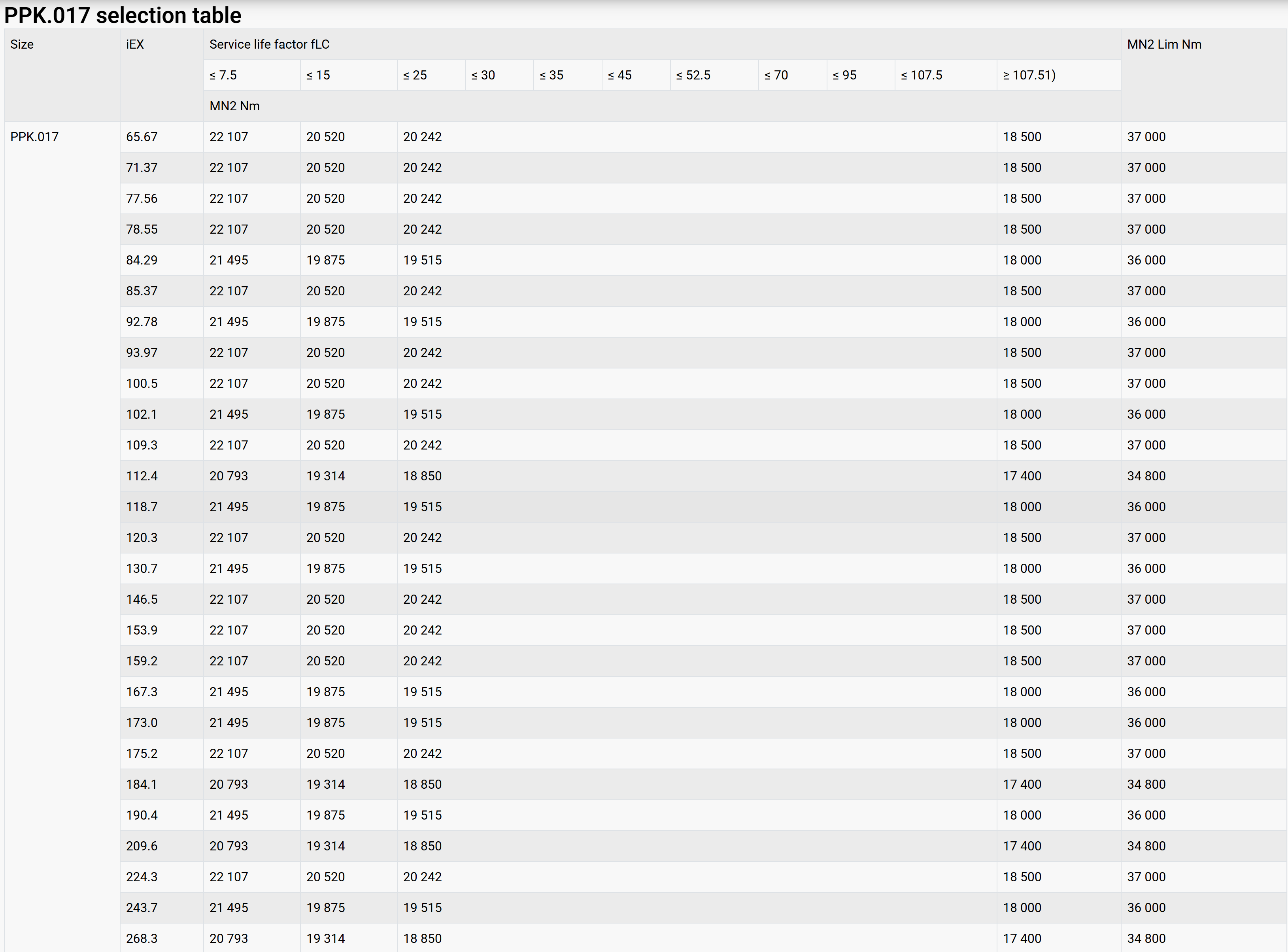

The SEW PPK Series Precision Planetary Gearbox offers outstanding advantages in precision, torque density, and durability, serving as a versatile core drive for diverse industrial applications requiring high positional accuracy and heavy-load capacity. Its advanced planetary gear configuration delivers exceptional torque density, enabling compact design while handling torque outputs from 50 to 15,000 Nm—ideal for equipment with limited installation space but demanding power requirements. Precision-machined gear components, compliant with DIN 3990 standards, ensure over 97% transmission efficiency, minimizing energy loss and operational noise, while the optimized lubrication system reduces wear and tear, extending service life and lowering maintenance costs. The robust, rigid housing enhances structural stability, resisting vibration and external impacts to maintain consistent performance in harsh industrial environments. With a modular design and flexible mounting options, it seamlessly integrates with SEW motors and auxiliary equipment, adapting to automation lines, material handling systems, and precision machinery. Widely applied in robotics, CNC machine tools, conveyor systems, and packaging machinery, it excels in scenarios requiring precise motion control and reliable power transmission. It balances compactness, precision, and durability, meeting the rigorous demands of modern industrial workflows as a high-performance planetary gear solution. (Word count: 400)

description

Perfect for all heavy-duty applications

The load is distributed across multiple planet gears, resulting in a significantly higher power density and thus enabling smaller dimensions compared to other gear unit types. The PKK series planetary gear units are therefore perfect for all heavy-duty applications that require a robust, compact design and high gear ratios.

In addition to gear unit design such as flange and foot mounting, the variance at the input and output offers great flexibility for the user. On the output end, a solid shaft with key and a splined solid shaft are available. As a hollow shaft gear unit, you can choose between a splined hollow shaft and a hollow shaft with shrink disk. On the input gear end, the motor connection is made either via an exposed shaft-end or a motor adapter. Access to the complete modular motor system from SEW-EURODRIVE with extensive options such as brakes and encoders also offer further degrees of freedom.