Weigao ARA-Series Spiral Bevel Gear Commutator: Precision Steering & Low-Noise Transmission Solution

I. Product Overview

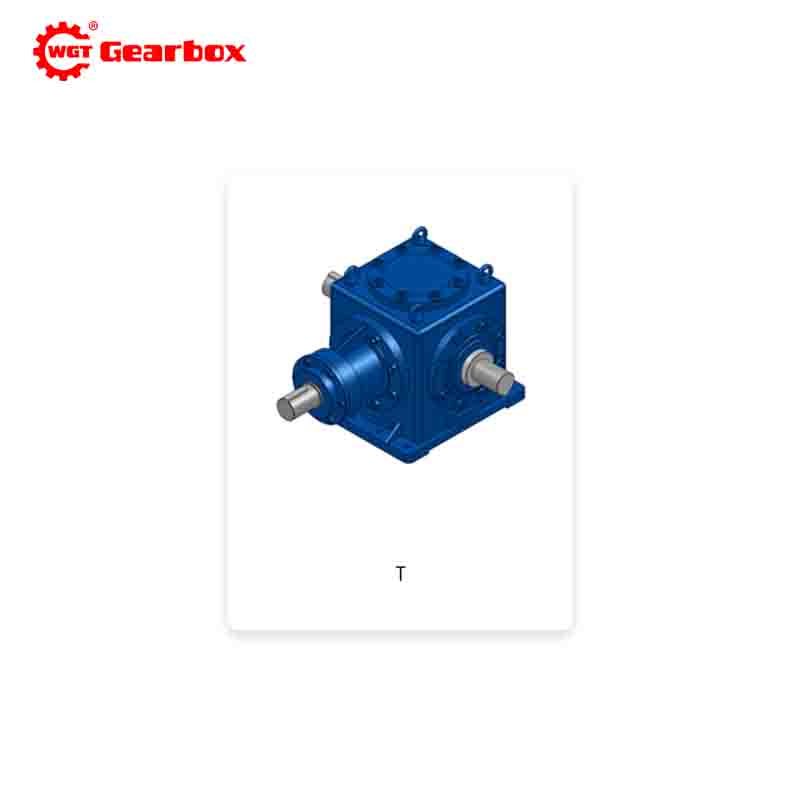

Weigao ARA-Series Spiral Bevel Gear Commutator is a high-precision transmission device integrating optimized spiral bevel gear structure and multi-directional steering function. As a specialized commutator for industrial power steering scenarios, it is tailored for equipment requiring direction switching such as lifting machinery, conveyors, and precision actuators. It overcomes the shortcomings of traditional bevel gear commutators such as poor steering stability, high operating noise, and limited installation flexibility. Compliant with GB/T 10095-2018 and ISO 6336 precision standards, with IP65/IP66 graded protection, it features 20CrNiMo alloy spiral bevel gears, high-rigidity cast iron housing, and composite sealing system. Boasting advantages of precise steering, low-noise meshing, flexible installation, and strong impact resistance, it operates stably at -30℃ to +110℃, serving as a core steering component for industrial transmission systems worldwide.

II. Core Advantages

1. Compound Gear Transmission, Pump-Specific Speed Matching

Adopting high-precision spiral bevel gear design with optimized tooth contact pattern, the ARA series realizes smooth power transmission and accurate direction switching. Gears are crafted from 20CrNiMo alloy steel, undergoing deep carburizing quenching, five-axis precision grinding, and tooth profile modification, with tooth surface hardness up to HRC 60-64 and roughness ≤Ra 0.025μm. The spiral tooth structure ensures continuous line contact meshing, increasing contact area by 35% compared with straight bevel gears, which significantly reduces tooth surface pressure and operating noise. Transmission efficiency reaches 95%-97%, with torque density up to 18Nm/cm³, and steering accuracy controlled within ±0.05°. The optimized gear backlash (≤5arcmin for standard grade, ≤2arcmin for precision grade) ensures stable steering without jitter, enabling the commutator to withstand 3 times rated load instantaneous impact, suitable for frequent start-stop and direction switching scenarios.

2. Model-Graded Design, Scenario-Specific Adaptation

The ARA series adopts modular design with multiple models covering diverse power and steering needs, supporting flexible installation in various equipment layouts. It covers transmission ratio 1:1-10:1, power range 0.75kW-110kW, and rated torque 500Nm-25000Nm, with 90° vertical steering as standard and 45°/60° optional steering angles. The housing adopts integral cast iron structure with reinforced rib layout, enhancing torsional rigidity by 30% and ensuring precise gear alignment under heavy load. It supports multiple installation modes including foot-mounted, flange-mounted, and shaft-mounted, with standardized connection interfaces adapting to different motor and equipment configurations. The compact structure reduces installation space by 25% compared with traditional commutators, facilitating integration into space-constrained equipment.

3. Magnetic-Mechanical Composite Sealing, Ultra-Harsh Environment Adaptation

Targeting complex industrial environments, the series adopts composite sealing and anti-pollution design to ensure long-term stable operation. Standard models adopt IP65 protection, combining multi-lip oil seal, labyrinth structure, and O-type sealing rings to effectively resist dust, cutting fluid, and light chemical corrosion. Enhanced models upgrade to IP66 with corrosion-resistant coating and pressure-resistant housing, adapting to humid, dusty, and corrosive working conditions such as machining workshops and outdoor machinery. The optimized spiral gear meshing design controls operating noise to ≤52dB at 1m, meeting precision workshop noise standards. The housing surface adopts anti-rust coating passing 1500-hour salt spray test, ensuring stable operation at -30℃ to +110℃ in extreme temperature environments.

4. Pump-Adapted Lubrication, Low Maintenance Cost

The lubrication system is optimized for frequent steering and continuous operation: small-medium power models use fully synthetic gear oil (ISO VG 150) for oil bath lubrication, realizing maintenance-free operation within 15000 hours; large-power models adopt forced lubrication with micro oil pump, ensuring uniform lubrication of gear pairs. The system is equipped with oil sight glass, temperature indicator, and oil drain plug for convenient status monitoring and maintenance. The first oil change is recommended after 500 hours of initial operation, and subsequent oil changes every 8000 hours under rated load. The modular structure allows quick disassembly of gear sets and seals, with standardized spiral bevel gear accessories ensuring consistent steering precision after overhaul, reducing maintenance downtime by 40%.

III. Typical Application Fields

- Lifting Machinery: Crane hoisting mechanisms, ARA series with precise steering and high torque ensuring stable direction switching during lifting

- Conveyor Systems: Belt conveyor steering units, low-noise meshing adapting to long-term continuous operation in workshops

- Precision Actuators: CNC machine tool feed mechanisms, high-precision steering controlling movement accuracy of mechanical components

- Construction Machinery: Forklift steering systems, compact structure and strong impact resistance adapting to outdoor operation

- Material Handling: Automated warehouse stacker steering modules, flexible installation matching equipment space layout

IV. Key Technical Parameters

| Model Series | Transmission Ratio Range | Rated Torque | Lubrication Mode | Protection Grade |

| ARA-Small (0.75kW-15kW) | 1:1-5:1 | 500Nm-3000Nm | Oil Bath Lubrication | IP65 (Optional IP66) |

| ARA-Medium (11kW-45kW) | 1:1-8:1 | 2500Nm-12000Nm | Oil Bath Lubrication | IP65 (Optional IP66) |

| ARA-Large (37kW-110kW) | 1:1-10:1 | 10000Nm-25000Nm | Forced Lubrication | IP65 (Optional IP66) |

V. Installation & Maintenance

Select models based on steering angle, rated power, and installation space (refer to the specification table). Use precision alignment tools to ensure gear coaxiality error ≤0.01mm during installation, fasten bolts with specified torque (30-120N·m for small models, 100-200N·m for large models) in diagonal sequence. Regularly inspect oil level, sealing performance, and gear meshing status, clean the housing surface and ventilation components monthly. Avoid overload operation exceeding 3 times rated torque, and use dedicated fully synthetic gear oil to ensure steering stability. Entrust maintenance to professional technicians familiar with spiral bevel gear commutator systems.

Weigao ARA-Series Spiral Bevel Gear Commutator adheres to the philosophy of "precision steering, low-noise reliability, and flexible adaptation". Its optimized spiral bevel gear structure and modular design break through traditional commutators' steering and installation limitations, ensuring reliable operation in industrial steering scenarios. Backed by strict quality control and professional after-sales service, it provides customized transmission solutions for lifting machinery, precision equipment, and material handling industries, establishing itself as a trusted global partner in industrial steering transmission.

Download

English

English