Understanding YE3 Motor Energy Efficiency Ratings: A Guide for Industrial Applications

What Are YE3 Motors and Their Energy Efficiency Ratings?

YE3 motors are a class of high-efficiency three-phase asynchronous motors developed to meet stringent international energy standards, such as the IEC 60034-30-1 classification. The YE3 motor energy efficiency rating typically falls under the IE3 (Premium Efficiency) level or higher, indicating superior performance compared to older models like YE2 (IE2) or standard motors. These ratings are crucial for industries aiming to cut electricity consumption and comply with regulations. For instance, a motor manufacturer specializing in YE3 designs ensures that each unit undergoes rigorous testing to verify efficiency, often achieving up to 95% or more under optimal conditions. This translates to significant savings over the motor's lifespan, making them a smart investment for businesses focused on sustainability.

Benefits of Upgrading to YE3 Motors in Industrial Settings

Adopting YE3 motors offers multiple advantages beyond just energy savings. First, they reduce heat generation, which extends the motor's lifespan and lowers maintenance costs. This is particularly beneficial in demanding environments where motors run continuously, such as in manufacturing plants or HVAC systems. Second, the improved efficiency contributes to a smaller carbon footprint, aligning with corporate social responsibility goals. When sourcing from a reliable motor supplier, companies can access customized solutions, including integration with variable frequency motor systems. These systems allow for precise speed control, further enhancing energy savings by adjusting power output based on load requirements. For example, pairing a YE3 motor with a variable frequency drive (VFD) can reduce energy use by up to 30% in applications like pumps or fans.

Integrating YE3 Motors with Other Motor Types and Components

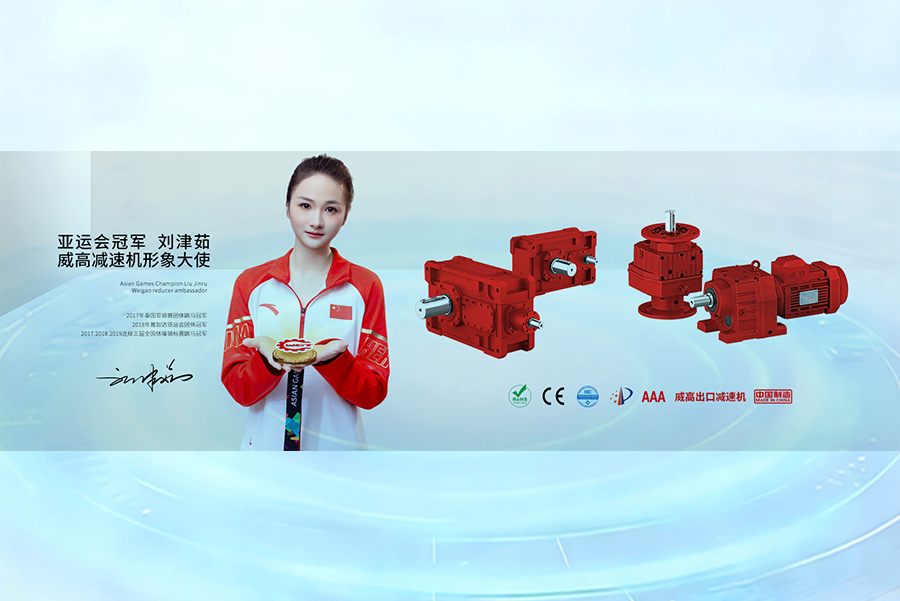

YE3 motors are often used in conjunction with specialized motors to meet diverse industrial needs. A brake motor, which includes an integrated braking mechanism, can be combined with a YE3 motor for applications requiring quick stopping, such as conveyor belts or cranes. This combination ensures safety without compromising efficiency. Similarly, an explosion-proof motor designed for hazardous areas can incorporate YE3 technology to provide both protection and energy savings in industries like oil and gas. Additionally, a gearbox is commonly paired with YE3 motors to adjust torque and speed, optimizing performance in machinery like mixers or extruders. For businesses seeking comprehensive solutions, platforms like WGTmotor.com offer a wide range of products, from standalone YE3 motors to complete systems with gearboxes and controls, simplifying procurement and installation.

Practical Tips for Selecting and Maintaining YE3 Motors

To maximize the benefits of YE3 motors, proper selection and maintenance are key. Start by consulting with a reputable motor manufacturer or supplier to assess your specific application requirements, such as power rating, operating environment, and load characteristics. Ensure the motor's efficiency rating matches your energy goals—for instance, opting for IE3 or higher if regulations mandate it. Regular maintenance, including cleaning, lubrication, and monitoring for vibrations, can prevent efficiency losses over time. It's also advisable to conduct energy audits periodically to track savings and identify potential upgrades. When integrating with other components, verify compatibility; for example, check that a variable frequency motor drive is compatible with the YE3 motor to avoid issues like overheating or reduced lifespan.

Common Questions

What is the difference between YE2 and YE3 motor energy efficiency ratings?

YE2 motors typically correspond to IE2 (High Efficiency) standards, while YE3 motors meet IE3 (Premium Efficiency) or higher. This means YE3 motors consume less electricity for the same output, offering better long-term savings and environmental benefits.

How can I find a reliable motor supplier for YE3 motors?

Look for suppliers with certifications, positive customer reviews, and a broad product range. Online platforms like WGTmotor.com provide access to multiple manufacturers, making it easier to compare options and get technical support.

Are YE3 motors compatible with variable frequency drives?

Yes, most YE3 motors are designed to work well with variable frequency drives (VFDs). However, it's essential to choose a VFD that matches the motor's specifications to ensure optimal performance and avoid damage.

Can YE3 motors be used in hazardous environments?

Yes, by selecting explosion-proof versions that incorporate YE3 technology. These motors are built to prevent ignition in flammable atmospheres, making them suitable for industries like chemical processing.

What maintenance is required for YE3 motors?

Regular inspections, cleaning of vents, lubrication of bearings, and monitoring of electrical connections are recommended. Following the manufacturer's guidelines helps maintain efficiency and extend the motor's life.